![]()

The WPL HiPAF range offers bespoke SAF (submerged aerated filter) sewage treatment plant solutions specifically designed to meet demanding , individual site requirements.

Why HiPAF?

HiPAF combines versatility , efficient processing , reliability and robust design , meeting all Environment Agency standards while minimising visual impact on the landscape.

With more than 1 ,400 units installed throughout the UK and overseas , the HiPAF is regularly specified by Water Utility first time sewerage schemes and upgrades to rural works , including United Utilities , Yorkshire Water , Anglian Water and Southern Water. It is also the preferred choice in many commercial and domestic applications that are not connected to mains drainage.

The HiPAF Compact sewage treatment plant contains primary settlement , biological treatment and final settlement modules in GRP (Glass Reinforced Plastic) and can be installed above or below ground.

It provides treatment for Biological Oxygen Demand (BOD) , Suspended Solids (SS) and ammonia (NH4) in wastewater applications for populations ranging from 1-60 people. With an optional ‘add-on’ sand filter , it will attain a treatment quality of BOD 10mg/l: SS 10mg/l: Ammonia 2mg/l.

Benefits

- Copes with variable flows and loads with unique flow balancing in primary tank

- Reliable operation and stand-by facility

- Low maintenance required as the HiPAF has no internal mechanical moving

parts - Safe , clean , accessible air diffuser system with large access lids for easy

maintenance - No emptying of tank required during maintenance of air distribution system

- Humus and primary sludge are stored in one place for simple tankering

operation - Small installation footprint , low installation costs , minimal visual impact

HiPAF treatment process

Primary Settlement

Primary settlement is in accordance with BS6297 , giving the required hydraulic retention time and ensuring that 30% of the BOD will settle out in the primary tank. The HiPAF Compact plant has sludge storage integral to the primary tank.

The primary settlement tank is equipped with baffles to prevent floating scum entering the biological phase of the treatment process. It also incorporates WPL’s unique forward feed system which lowers the level in the tank , during periods of low flow , to provide a buffering capacity for possible surges in the influent. The forward feed also mitigates process risks associated with variable loads.

Biological Treatment

After primary settlement , the settled liquor flows to the biological treatment unit by displacement and via the air lift forward feed. The biozone is fully segmented internally to eliminate the risk of process short cuts and to provide an efficient nitrifying environment. Each biozone segment is filled with high voidage plastic filter media , where both carbonaceous and nitrifying processes take place. Air to oxygenate the influent and to scour excess biomass from the filter media is introduced continuously below each chamber by a series of diffusers.

Final Settlement

Following biological treatment the effluent flows into the final (humus) settlement tank where the excess biomass settles out. The humus tank is equipped with air lifts which are arranged to automatically transfer settled humus sludge to the primary tank for co-settlement. The treated effluent flows under gravity to the works outfall.

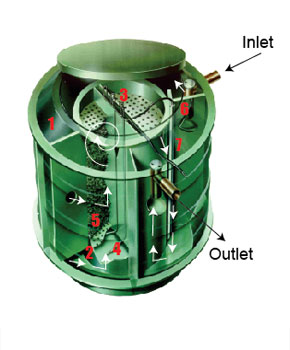

Cut-away graphic showing the treatment process through a WPL HiPAF Compact

| 1 Primary settlement tank2 Settled solids at bottom

3 Biological treatment unit (biozone) 4 Air diffusers at the bottom of 5 Filter media |

|

6 Settled sludge air lift back to primary7 Final (humus) settlement tank |

Control kiosk

Each HiPAF comes complete with a discreet , weatherproof , acoustically lined GRP kiosk , situated above ground. This houses the blower(s) , a Form 2 control panel and air distribution manifold.

Included as standard is 10m of airline , to connect the blowers to the tank. Blower and airline upgrades are available if the kiosk is sited further than 10m from the plant.

The Form 2 control panel automatically controls the operation of the plant (Form 4 is also available).

Please contact us or talk to your authorised distributor for advice.

Additional extras and upgrades

- Lid colour finish options are available

- Single or three phase electrics

- Tertiary treatment options for more stringed consent standards

- Inverts up to 1.5m with turret extensions

- Separate Robust Aerobic Digestion System (RADS) sludge handling and sludge

digestion - Volt-free telemetry contacts on control panel

- Form 4 control panel

- Pumped inlet flow control chamber

- Above ground (pictured) or below ground solutions

- Permanent or temporary solutions

- Blower and airline hose upgrades

HiPAF is the ideal sewage treatment solution for:

- Camping and caravanning sites

- Smaller hotels

- Restaurants and public houses

- Farms

- Garden centres

- Stables/kennels

- Stately homes and large country estates

- Nursing homes

- Abattoirs

- Rural industrial buildings and offices

- Golf courses

- International projects