A Range of High Capacity Pumping Systems for Domestic & Commercial Applications

Pump Station Enquiry:

To allow us to accurately size and quote your specific system, please complete either our Online Pump Station Enquiry Form or alternatively, print our PDF Pump Station Enquiry Form and post or fax it to us.

Once we have received your enquiry form we will then evaluate your requirements and specify the appropriate system accordingly to allow us to provide a suitable quotation.

High Capacity Pump stations are suitable for the following applications

The Pumpstor24 range is suitable for the following applications:

- Housing developments with up to 24hr storage requirements (10 – 500 houses)

- Commercial developments

- Industrial developments

- Hotels and restaurants

- Caravan and camping sites

For temporary storage solutions click here.

Designed for Quality, Reliability & Peace of Mind

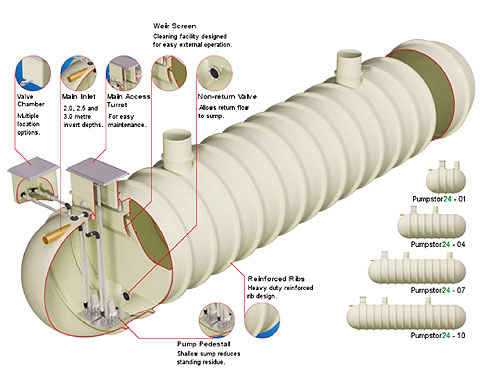

The 2.6m Horizontal Pumping Station is manufactured from robust GRP and incorporates a 100mm reinforcing rib at 770mm intervals. The construction has an 8mm nominal wall thickness to provide a durable and rigid tank system.

The station is designed to incorporate the pump sump at one end of the tank. An integral wall separates the sump section from the holding tank section.

The integral wall has an overflow to allow the effluent to pass to the holding tank in a high level situation. The overflow is screened to 12mm particle size to prevent floating debris and grease from passing from the sump to the holding tank, thereby easing the cleaning process. At a low level in the integral wall, a non-return valve is installed to allow the flow to return to the sump when the system becomes operational again.

The system is simple in design and construction for ease of maintenance.

Features

- Manufactured in the UK

- Single tank installation up to 80m³ (multiple tank systems available)

- Multiple valve chamber location and invert options

- Weir cover screen prevents solids passing into main storage chamber

- Unique weir screen cleaning facility removes need to access the chamber during maintenance

- High level alarm (as applicable)

- Totally sealed system

- Factory pre-fabricated under controlled conditions to ensure consistent high quality construction

- Minimal on-site assembly

- Owls Hall offer a full commissioning and after sales service involving planned maintenance visits. Please visit our servicing section for more information.

Benefits

- Easy to install – one piece tank chamber

- Less cranage requirements compared to concrete pumping stations

- On-site Health & Safety issues are minimised – no requirement for personnel to enter the tank during excavation on-site to complete installation work

- Reduced maintenance – easy cleaning out of holding tank

- Shallower excavation compared to concrete pumping stations

The comprehensive range of quality pumps offers solutions for most applications. Pump sizes range from 0.35kW to 12kW for the standard package pumping system.

Designed for Quality, Reliability & Peace of Mind

The 2.6m Horizontal Pumping Station is manufactured from robust GRP and incorporates a 100mm reinforcing rib at 770mm intervals. The construction has an 8mm nominal wall thickness to provide a durable and rigid tank system.

The station is designed to incorporate the pump sump at one end of the tank. An integral wall separates the sump section from the holding tank section.

The integral wall has an overflow to allow the effluent to pass to the holding tank in a high level situation. The overflow is screened to 12mm particle size to prevent floating debris and grease from passing from the sump to the holding tank, thereby easing the cleaning process. At a low level in the integral wall, a non-return valve is installed to allow the flow to return to the sump when the system becomes operational again.

The system is simple in design and construction for ease of maintenance.

Pump Chamber Dimensions

| Model | Overall Length (mm) | Total Storage Capacity (ltr) |

24 Hour Storage Capacity (approx) | ||

|---|---|---|---|---|---|

| 0.5-2.0m Invert (ltr) | 2.5m Invert (ltr) | 3.0m Invert (ltr) | |||

| PSTOR24-01 | 4,314 | 18,302 | 6,985 | 5,578 | 3,665 |

| PSTOR24-02 | 5,076 | 22,348 | 6,985 | 5,578 | 3,665 |

| PSTOR24-03 | 5,843 | 26,420 | 10,771 | 8,566 | 5,688 |

| PSTOR24-04 | 6,610 | 30,493 | 14,582 | 11,574 | 7,724 |

| PSTOR24-05 | 7,380 | 34,581 | 18,393 | 14,582 | 9,761 |

| PSTOR24-06 | 8,150 | 38,669 | 22,219 | 17,602 | 11,805 |

| PSTOR24-07 | 8,915 | 42,730 | 26,044 | 20,622 | 13,849 |

| PSTOR24-08 | 9,680 | 47,748 | 29,845 | 23,622 | 15,880 |

| PSTOR24-09 | 10,451 | 50,886 | 33,646 | 26,623 | 17,911 |

| PSTOR24-10 | 11,222 | 54,979 | 37,477 | 29,646 | 19,587 |

| PSTOR24-11 | 13,523 | 67,196 | 44,308 | 32,670 | 22,005 |

| PSTOR24-12 | 15,065 | 75,383 | 52,704 | 41,694 | 28,114 |

This Chart is a general guide

Legal Requirements

Prior to installation, there is a legal requirement to obtain permission from the appropriate agencies (including connection to a public sewer).

24hr Storage to Meet Building Regulations

The pump station range has been designed in accordance with Building Regulations Document H1 Foul Drainage, page 16. (Pumping Installations) Section 2.39. This states:

“Where foul drainage from a building is to be pumped, the effluent receiving chamber should be sized to contain 24 hour inflow to allow for disruption in service. The minimum daily discharge of foul drainage should be taken as 150 litres per head per day for domestic use. For other types of building, the capacity of the receiving chamber should be based on the calculated daily demand of the water intake for the building. Where only a proportion of the foul sewage is to be pumped, then the capacity should be based pro-rata. In all pumped systems the controls should be so arranged to optimise pump operation. The required 150 litres per head per day volume should reflect the storage volume in the station pump or station and overflow tanks.”

Ref: page 16. (Pumping Installations) Section 2.39

All Klargester products have a full initial 12 month warranty covering all mechanical and electrical components against malfunction, provided the unit has not been subject to damage or abuse.

Owls Hall offer a full Installation service. Please visit our Installation section for more information.

Pump Station Enquiry:

To allow us to accurately size and quote your specific system, please complete either our Online Pump Station Enquiry Form or alternatively, print our PDF Pump Station Enquiry Form and post or fax it to us.

Once we have received your enquiry form we will then evaluate your requirements and specify the appropriate system accordingly to allow us to provide a suitable quotation.